Rubber Release Agents & Additives

Internal Release Agents, External Release Agents, Lubricants & Additives for all rubber manufacturing.

Greatly reduced mould build up.

Releases with no silicone, stearate or natural wax.

Improved surface finish, no blooming.

Highly efficient water-based externals.

Improved hot tear resistance.

Special products for peroxide cure EPDM and rubber metal bonding.

Improved filler dispersion.

Higher physical properties.

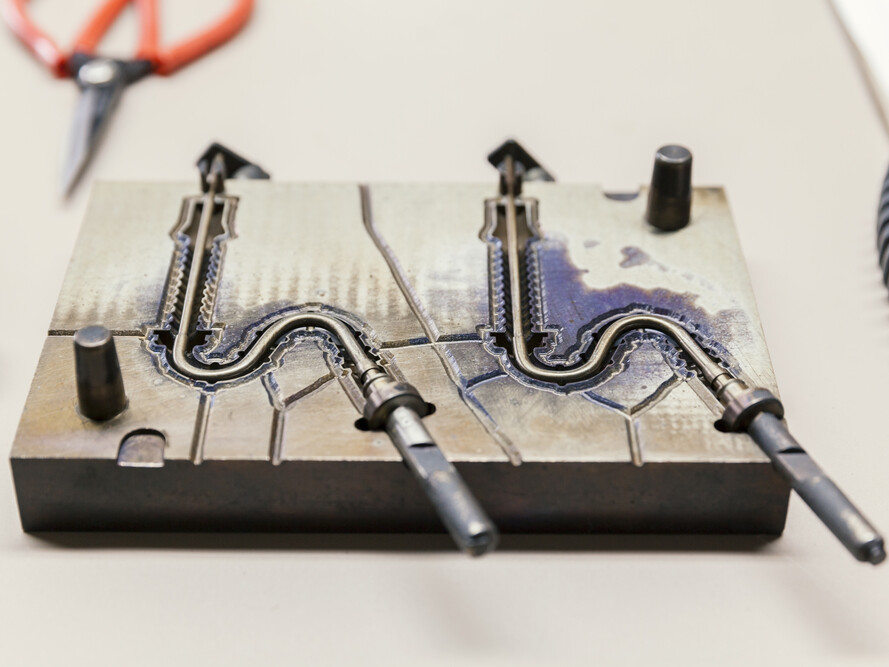

Consistent and accurate finish exactly copying mould contours.

Food contact and medical grades available.

We offer a wide range of internal release agents, external release agents, lubricants and additives for most application fields of the rubber industry. More than 50 years experience have resulted in a product range providing a high manufacturing quality and safety, minimizing ecological impact and reducing production costs.

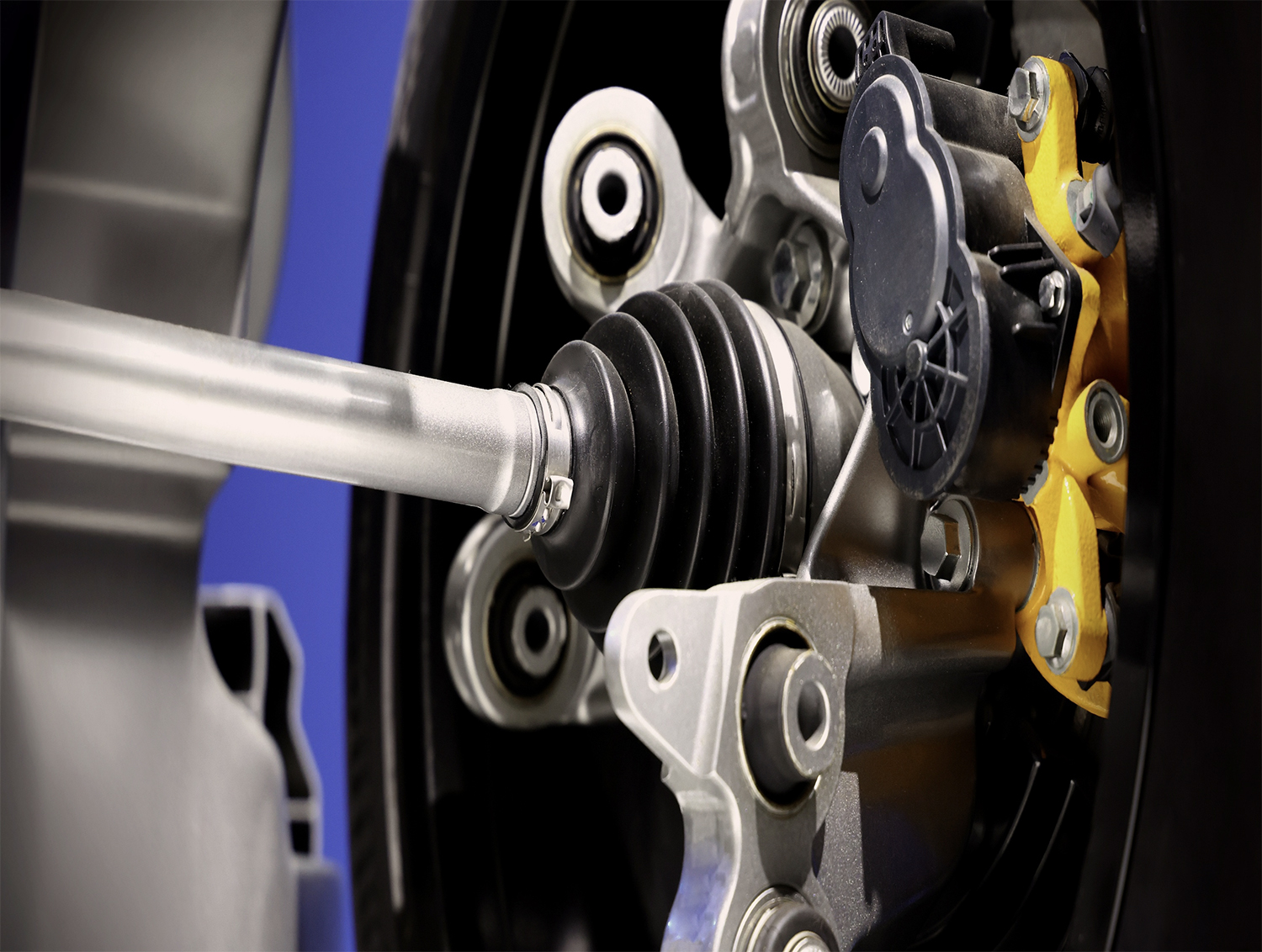

Rubber to metal bonded applicationsAVS. - Zero contamination.

Tyres – General purpose & Anti Rust applications.

General rubber goods.

Specialist rubber products.HNBR, Chlorinated

Mould Fouling

In order to reduce the costs caused by bad unmoulding, rapid mould dirtying and too high reject rates we recommend the use of external and/or internal release agents and lubricants which are rationalizing the manufacturing process.

Once the first traces of deposits appear on the mould surface, a rapid increase of mould dirtying will follow. The subsequent cleaning process in most cases is too frequent, too long and too expensive.

Efflorescence

Eliminate problems with efflorescence, this can appear on rubber products that are exposed to moisture, have poor curing or contamination during moulding.

Working closely with our partners we can provide the perfect solution for your moulding process. If you could please

fill out the below form with your process details, issues or requirements we will determine what the best products we

can offer for you to trial.