Thermoplastics

Enhancing Thermoplastic Processing with Advanced Additives

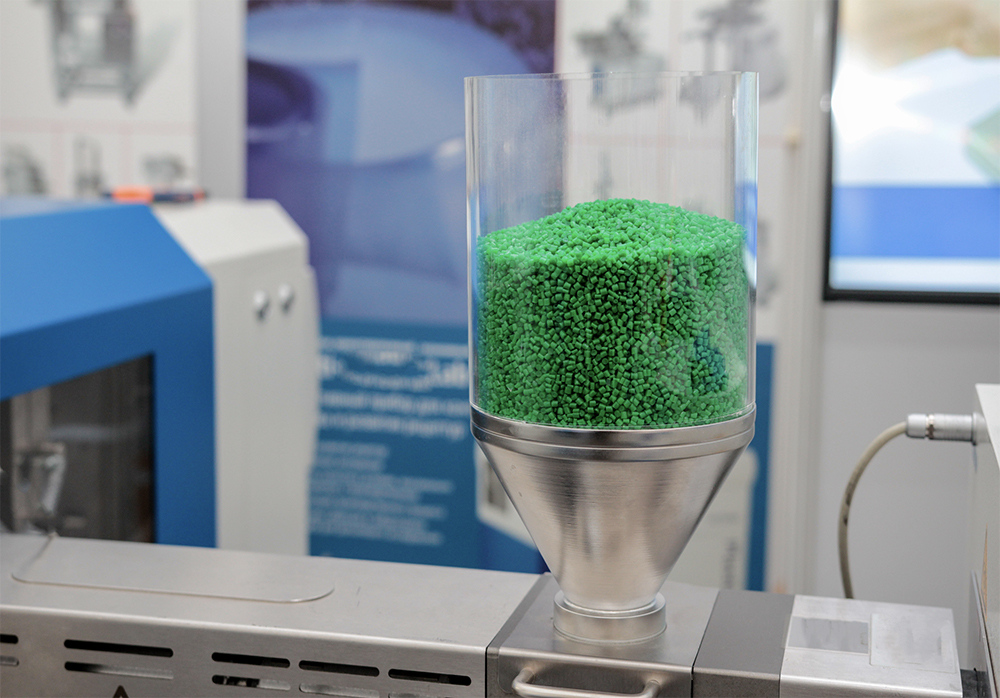

Thermoplastics are moulded using various techniques such as injection, compression, and extrusion moulding. Today, the use of release agents, lubricants, and process additives is essential for efficient production.

In addition to providing excellent release properties, these additives improve the overall manufacturing process—promoting better dispersion of pigments, fillers, and fibres for a more consistent and homogeneous material mix. They also help increase output rates, minimise build-up, and significantly reduce abrasion on machine parts, extending equipment life and improving productivity.

Internal Release Agents & Lubricants

Stabilizers

Flavoring Agents/ Smell Neutralizer

Release Agents for underwater granulation

External Release Agents

Get the Right Solution for Your Process

Every thermoplastic moulding application has its own challenges—and choosing the right release agents and additives is key to achieving the best results. To help us recommend the most suitable products for your specific process, please take a moment to fill out the form below. By understanding your materials, moulding method, and production needs, we can tailor a solution that enhances performance, improves efficiency, and protects your equipment.

Our technical team will recommend the best-suited products for your application, providing detailed information along with a free sample offer.